Iphutha lefomethi ye-imeyili

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

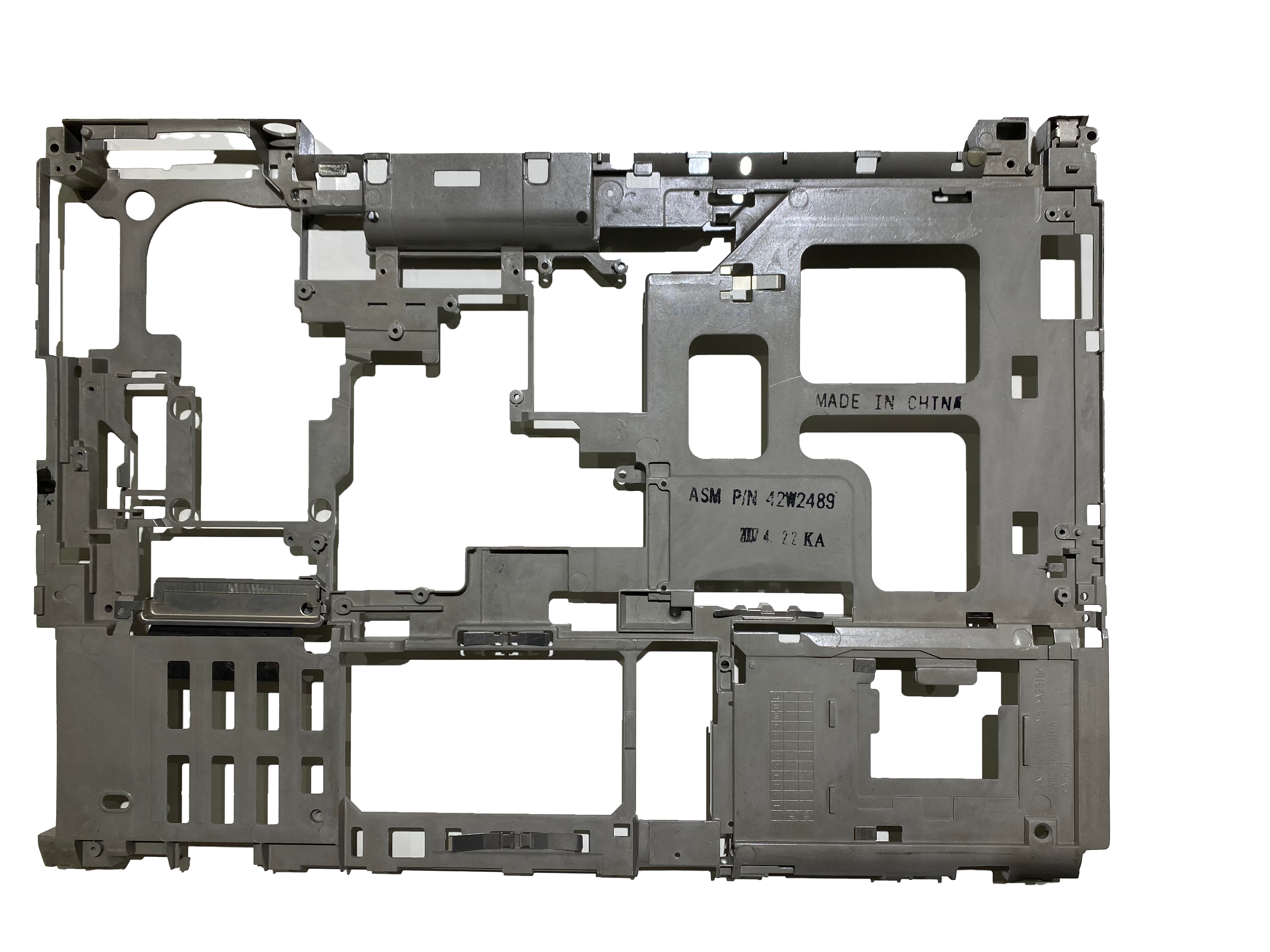

I-Automotive magnesium alloy

Ukuphila kwe-die kunganwetshwa kakhulu uma kuqhathaniswa nokufaka ukufa kwe-aluminium.Lokhu kungenxa yezakhiwo zokudlulisa ukushisa kwe-magnesium kanye nokuncipha kokusondelana kwayo nensimbi, okuholela ekuthengiseni okungenamsebenzi kanye nokuguguleka okuncane.

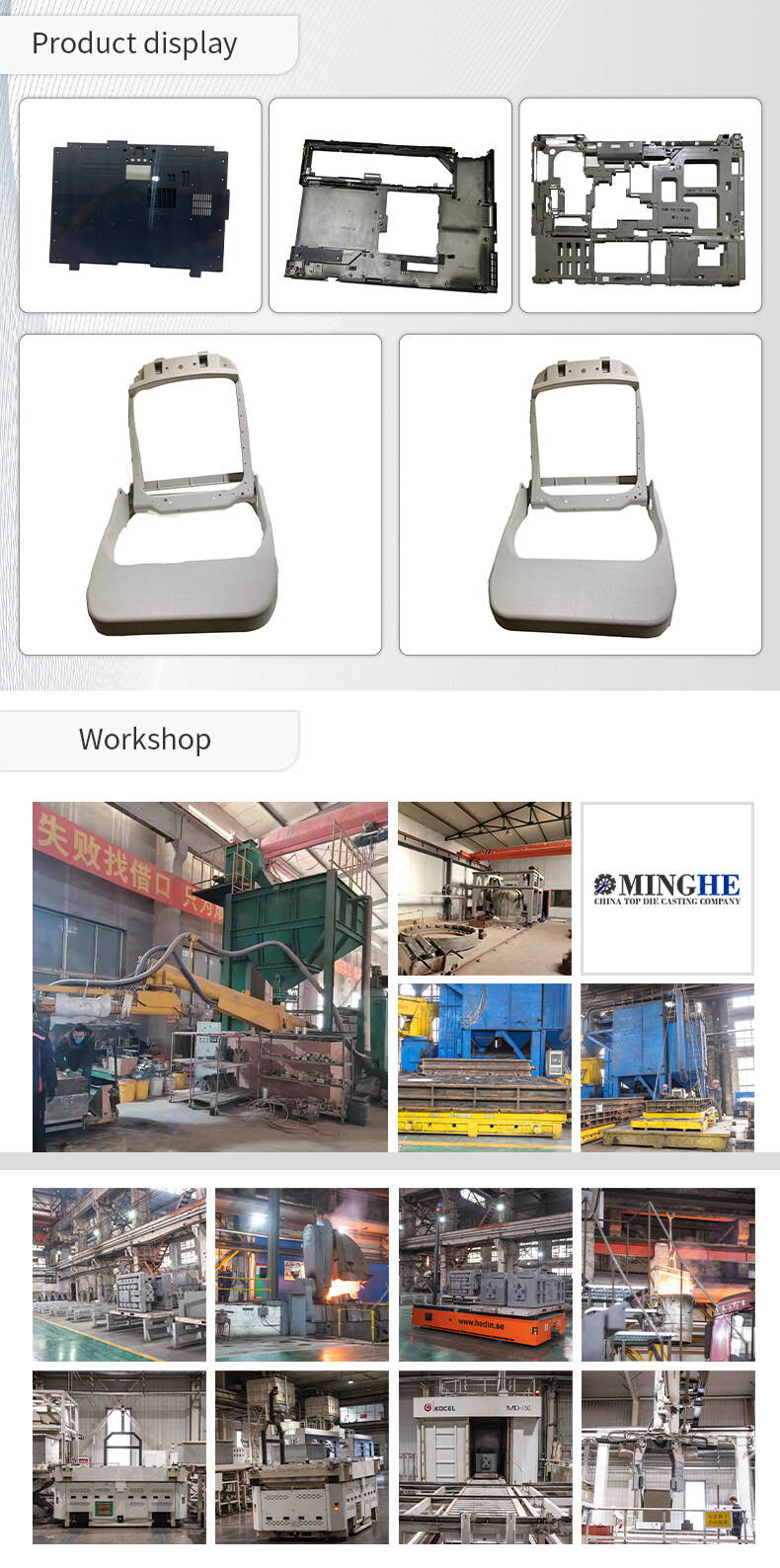

Iphrofayela Yenkampani

UMinghe ungumkhiqizi wembulunga yonke, osebenza ngokugcwele wemikhiqizo yokusakaza ye-precision die.Njengoba sinesipiliyoni seminyaka engaphezu kwengu-35 ocwaningweni nasekuthuthukisweni, ekukhiqizeni, nasekulungiseni imishini ye-aluminium, zinc kanye ne-magnesium, siyaziqhenya ngokusebenzisana nezinye zezinkampani ezihamba phambili emhlabeni zezimoto, zobunjiniyela, zikagesi, nezokuxhumana.

Sihlinzeka ngobunjiniyela abanolwazi, ukuphathwa kobuchwepheshe, namaqembu okuqinisekisa ikhwalithi alungele ukusekela amaphrojekthi ayinselele kakhulu.Sisize amakhasimende ngama-prototypes enziwe ngokunemba, idizayini yokufa, ukuhlolwa okubanzi komkhiqizo, kanye nokukhiqizwa kwevolumu.

Ukucatshangelwa kweMagnesium Alloy Die Casting Production

Die Life

Uma kuqhathaniswa ne-die casting ye-aluminium, impilo ye-die ingathuthukiswa kakhulu.Lokhu kungenxa yesici sokudlulisa ukushisa kanye nokuncipha kobudlelwane ne-iron ye-magnesium, okuholela ekufakweni kwe-solder okungenamsebenzi kanye nokuguguleka okuncishisiwe.

Ukukhiqiza

Ngenxa yokuthi izinga lokushisa le-magnesium liphansi kune-aluminium, insimbi iqina ngesivinini esisheshayo, ikhiqize izikhathi zomjikelezo ezimfushane, ngokuvamile ngo-15-25%.Ukuzinza kobukhulu obukhethekile bomkhiqizo we-as-cast kuyisici esithile se-cast magnesium alloys.Imvamisa, imithi yokwelapha eqeda i-anneal noma ekudambisa ingcindezi ayidingeki nge-magnesium, ngokuphambene nalokho okwenzeka kwezinye izingxenye ze-aluminium esakazwayo lapho ukukhula okuthile kuqhubeka njengoba imiphumela yokuguga yemvelo yenzeka ngezikhathi ezinwetshiwe emazingeni okushisa aphakathi nendawo kuye phezulu.I-machinability ivelele, ibonisa izici ezingcono kakhulu zazo zonke izinto zesakhiwo okuwukuthi isikhathi somshini esincishisiwe, izidingo zamandla aphansi, ukuphila kwamathuluzi okude, ukuqedwa okuhle kakhulu kwendawo ngokuvamile ngokusikwa okukodwa kanye nokwakhiwa kwethuluzi elincane elinezindleko eziphansi zokuwenza.

Ukuzwela

Ngesikhathi somjikelezo wokulingisa ingxenye ngayinye yokulingisa izothuthukisa i-microstructure ebuswa izinga lokuqiniswa lendawo kanye nephethini.Idizayini elungile yokusakazwa kanye nesistimu yayo yokudla ibalulekile ukuze kuqinisekiswe iphethini yokuqina efanayo neqondisayo.Lapho lokhu kungafinyelelwanga, kulindelekile ukuthi ingxenye ethile ye-microporosity izokwakhiwa ngenxa yokufinyela kwevolumu ngesikhathi sokuqina.Lokhu kuzovimbela ukuzuzwa kwezakhiwo ezinhle kakhulu ezitholakala ku-die cast magnesium.I-Ductility ipharamitha ebalulekile ezwela inqubo enokulawulwa kwe-inhomogeneities, ukukhubazeka kanye nenqubo ebaluleke kakhulu ekuboneni amandla okusebenza kwesakhiwo.

FAQ

Unga-oda kanjani?

Okokuqala, iKhasimende lingasithumela isampula noma umdwebo wakho, njengomdwebo we-2D nowe-3D (ifomethi ye-IGS noma ye-STP).Okwesibili, onjiniyela bethu bazohlola umdwebo ngokucophelela bese bekunikeza inani elingcono.Okwesithathu, Uma wamukela, i-oda liqinisekisiwe.

Iphi imboni yakho?

Ifektri yethu etholakala e-Dongguan okuyidolobha elihle eliseduze kakhulu ne-Guangzhou ne-Shenzhen.Ungandizela e-Shenzhen Bao'an International Airport (ZGSZ) noma e-Guangzhou Baiyun International Airport (ZGGG), sizokulanda esikhumulweni sezindiza.

Ingabe uyifekthri noma inkampani yokuhweba?

Siyimboni.Sikunikeza isevisi yokuma okukodwa, kusukela ekwakhiweni kwesikhunta kuya ekuqedeni ingxenye.

Indlela yomkhumbi?

Isampula ye-die casting kanye ne-CNC machining noma i-oda elincane livame ukuthunyelwa yi-TNT, FEDEX, UPS njll, futhi i-oda elikhulu lithunyelwa ngomoya noma ulwandle ngemva kokuqinisekiswa kwamaklayenti.

Ithini imigomo yakho yokukhokha?

Izinkokhelo zesikhunta sokufa: inkokhelo ethuthukisiwe engu-40% ngemuva kokusayina inkontileka;

Ibhalansi engu-60% izokhokhwa ngemva kokugunyazwa kwesikhunta yikhasimende.

Isikhathi sokukhokha se-die casting order: T/T, 30% njengediphozithi ikhokhwe ngaphambi kokukhiqizwa yi-T/T, u-70% akhokhwe ngaphambi kokulethwa.