Iphutha lefomethi ye-imeyili

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Zonke Izigaba

Iyasakaza

(9)Ukulingisa izingxenye zendiza

Yakhiwe yizingxenye ezilandelayo: ikhanda, i-head fairing, i-oxidizer kanye ne-fuel (i-ejenti yomlilo) amathangi, indawo yensimbi, isigaba esiphakathi kwesiteji, isakhiwo sokuphonswa kwenjini, indawo yomsila, nezinye izingxenye.Imishini yokuxhuma ehlukene ikhona ezingxenyeni ezidinga ukuhlukaniswa.

Izingxenye zokusakaza

Ukunemba kobukhulu be-Premium, ngokuvamile obungu-0.1 mm ku-2.5 cm wokuqala (0.004 iyintshi eyintshi yokuqala) kanye no-0.02 mm ngesentimitha ngayinye eyengeziwe (kuncike ezintweni zokulingisa)

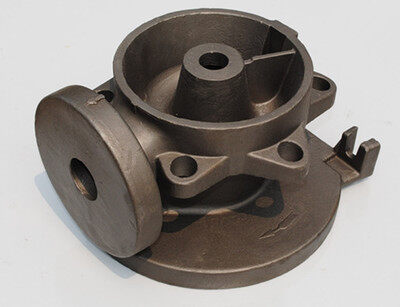

Ukuphonsa insimbi

Ama-castings enziwe kusetshenziswa indlela yokuphonsa isihlabathi adalwe ekubunjweni kwesihlabathi.Insimbi, insimbi, kanye neningi le-non-ferrous alloy castings kungakhiqizwa kusetshenziswa ukubunjwa kwesihlabathi.Ukubunjwa kwesihlabathi kungashintshwa ukuze kwenziwe ucezu olulodwa, ukukhiqizwa kwenqwaba, nokukhiqizwa kwenqwaba njengoba izinto zokumodela ezisetshenziswa kule nqubo zibiza imali eningi futhi kulula ukuzithola, futhi isikhunta silula ukwakha.Sekunesikhathi eside yavela esinyathelweni esibalulekile ekukhiqizeni okulingisayo.

Ukukhipha i-wax elahlekile

Ukufakwa kwe-investimenti, okubuye kubizwe ngokuthi ukuphonswa kwe-wax elahlekile, kuhilela izinqubo ezifana nokucindezela ingcina, ukuhlanganisa i-wax, ukuhlanganisa izihlahla, ukucwilisa udaka, ingcina encibilikayo, nokuphonsa insimbi encibilikisiwe.Ukwenza isikhunta se-wax sengxenye ezophonswa kusetshenziswa i-wax, bese usimboza ngodaka ukuze udale isikhunta sodaka, kwaziwa ngokuthi ukukhishwa kwe-wax elahlekile.Faka isikhunta sobumba esomile emanzini ashisayo ukuze uncibilikise isikhunta sangaphakathi se-wax.

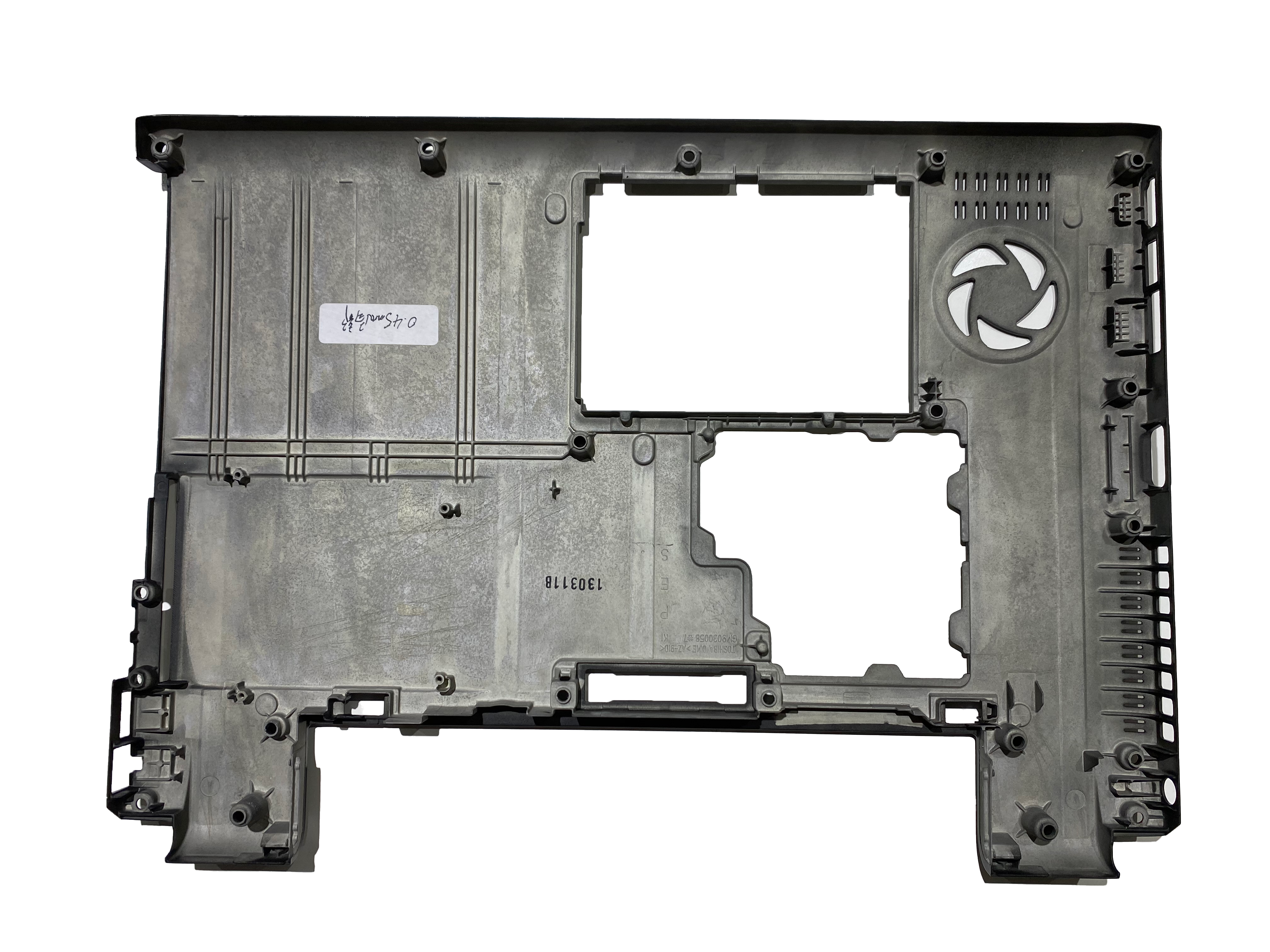

CNC Machining

(7)ubakaki we-aluminium

Isevisi yomshini we-CNC iyindlela enhle kakhulu yokunciphisa umjikelezo wokukhiqiza futhi wehlise izindleko zezingxenye zengxenye yomshini wakho.Izinsizakalo zemishini ye-CNC zingahle ziqondise inqubo yokukhiqiza, zisheshise ukukhiqizwa kwezingxenye ezinomshini, futhi zifinyelele izinga elikhulu lokunemba ngokuhlanganisa ubuchwepheshe obuhlukahlukene obusha.

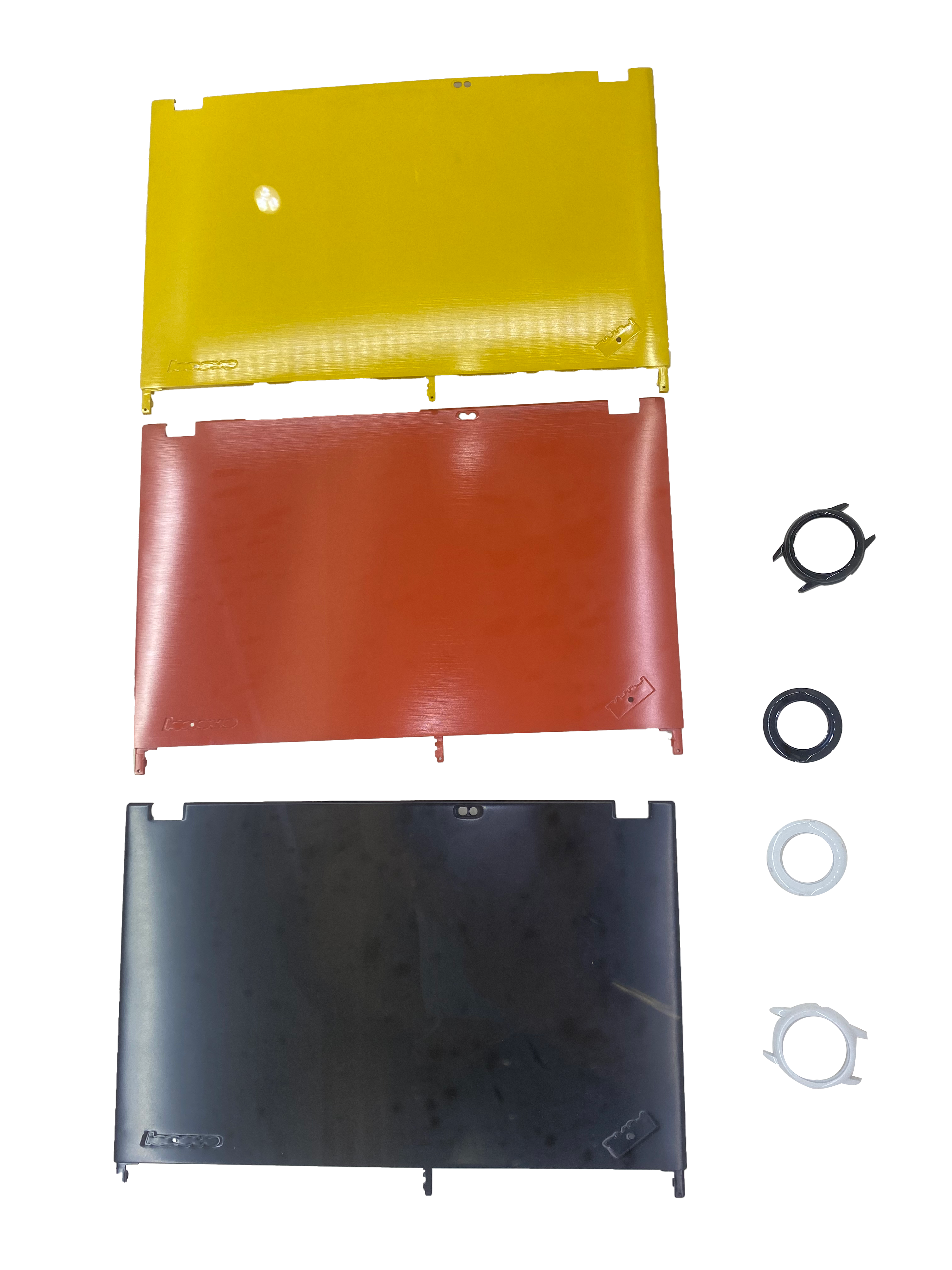

Iphaneli ye-aluminium

Izintengo eziphansi nekhwalithi ehlangabezana nezidingo zabo kungase kube izici ezimbili ezithonya izinqumo zamakhasimende amaningi zokusebenzisa amasevisi ethu.Intengo ayiseyona into yokuthuthukisa yokunquma umhlinzeki oqeqeshiwe, noma kunjalo, njengoba ukuthengiswa kwamanye amazwe kuqhubeka nokuthuthuka.

CNC Lathe Machining

Inqwaba yezindlela ezijwayelekile zokwenza imishini zithathelwe indawo yi-CNC lathe machining, ebaluleke kakhulu.Esikhathini esidlule, izingxenye zazikhiqizwa kusetshenziswa imishini ye-lathe esetshenziswa abantu.Kodwa namuhla, i-CNC lathe isithole ukuthandwa njengethuluzi lokwenza izingxenye.Ngisho noma le ndlela isizuze ukuthandwa okuningi, akuwona wonke umuntu onekhono ezintweni eziyisisekelo ze-CNC lathe machining.

CNC Milling machining

I-CNC machining iyindlela okuthi ngokwemvelo yayo inikeze amazinga amakhulu okunemba nokunemba kanye nethuba elincane kakhulu lamaphutha.Isizathu siwukuthi isebenza ngohlelo olushayelwa yikhompyutha futhi ifaka imiklamo ye-3D edalwe kusetshenziswa i-CAD (I-Computer-Aided Design).Isixhumi esibonakalayo somshini sisetshenziswa kuso sonke isenzo.Ukuze lo mshini wenze imiyalelo yawo, akukho okokufaka okwenziwa ngesandla okudingekayo.Izinga eliphezulu lokunemba lenziwa lenzeke ngalezi zinqubo ezizenzakalelayo, ukuqinisekisa ukuthi ngisho nejiyomethri eyinkimbinkimbi kakhulu futhi enomkhawulo ingaphathwa ngobuchwepheshe.

Ukulingisa ukufa

(5)I-Aluminium Die Casting

Okwezimoto, ezokwelashwa, i-aerospace, zikagesi, ukudla, ezokwakha, ezokuphepha, ezasolwandle, nezinye izimboni, sinikeza izinsizakalo zokulingisa ezenziwe ngokwezifiso ezikhiqiza ukulingisa okuthembekile nokunenani elifanele elihlangabezana nezimfuneko zakho.Thumela umbuzo wakho noma uhambise imidwebo yakho ngokushesha ukuze uthole isaphulelo samahhala ngokushesha ngangokunokwenzeka.

Izingxenye zokuphonsa ze-Precision Die

Ngokufana nokubumba umjovo, i-aluminium high pressure die casting ihlanganisa ukuthela insimbi encibilikisiwe egunjini lokubumba.Amasevisi okusakaza nge-Aluminium angasetshenziselwa ukudala izingxenye eziyinkimbinkimbi ezinamajiyometri ayinkimbinkimbi.Amabhulokhi enjini yezimoto, izingalo ze-rocker, ama-carburetor, izindlu zephampu yamanzi, izindlu ze-gearbox, izindlu ze-clutch, izindlu zokuqondisa, nezinye izingxenye zokukhiqiza ziphakathi kwezingxenye ze-aluminiyamu e-precision die cast.

Ukulingisa ukufa

Ziningi izindlela zenqubo ezisetshenziselwa ukuguqula izinto zensimbi zibe yimikhiqizo edingekayo, okuhlanganisa ukuphonswa, ukukhanga, ukukhushulwa, ukugingqika, ukudweba, ukunyathela, ukusika, i-powder metallurgy, nokunye.Indlela ebaluleke kakhulu, esetshenziswa kabanzi, futhi ebanzi phakathi kwazo ukuphonsa.Ukubunjwa kuhilela ukuthela insimbi encibilikisiwe esikhunjeni esingenalutho esakhiwe ngezinto ezikwazi ukumelana namazinga okushisa aphezulu, futhi ngemva kokujiya, umphumela wakheka ngendlela oyifunayo.

Isevisi yokulingisa ukufa

Idizayini Yokudweba: Onjiniyela bakwa-Minghe bakholelwa ukuthi i-DFM ingenye yezindlela ezingcono kakhulu zokuthuthukisa ukusebenza kokulingisa kuyilapho igcina ikhono labo lokwenziwa.Ithimba lonjiniyela abanekhono abangaphezu kweshumi eMinghe lizonikeza iseluleko esibalulekile mayelana nesakhiwo sezinto ezibonakalayo futhi lilinganise phakathi komklamo, izindleko, kanye nengxenye yendawo.