Iphutha lefomethi ye-imeyili

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Izindaba

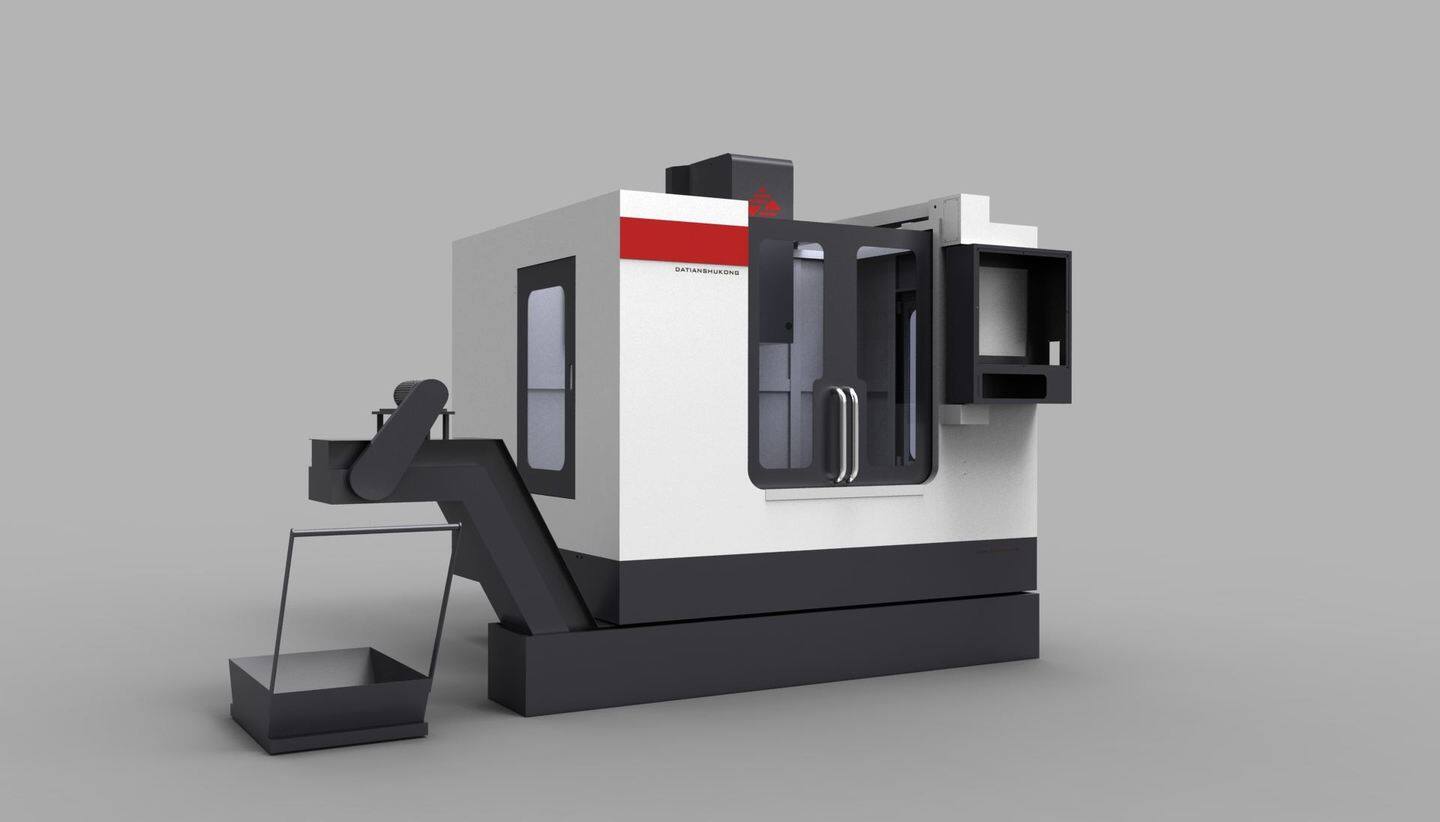

Types and Applications of Common Milling Cutters for Vertical CNC Milling Machines(2)

Common cutter for contour machining of Vertical CNC milling machine -- end mill

- definition of end milling cutter

An end milling cutter is a tool with a high utilization rate on a CNC milling machine, which can process planes, part contours, open grooves, and forming surfaces. The shape of the end milling cutter is cylindrical and generally has more than three edges. The main cutting edge is distributed on the cylindrical surface of the milling cutter, and the end face is the auxiliary cutting edge. The shape of the end face of the milling cutter has a central hole type or an open type.

- spiral angle of end milling cutter and its function

End mills are divided into a left-hand spiral and right-hand spiral. Milling edges are also divided into the left-hand edge and right-hand edge. The most common is the right-hand spiral. The edge on the cylindrical surface of an end mill can be either a straight edge or a helical edge. However, the straight edge is intermittent cutting, with large vibration and poor surface quality; The spiral edge is used for continuous cutting, and each cutter tooth gradually cuts in and out along the cutting edge, with little vibration, to improve the stability of the cutting process and the machining surface quality of the workpiece. The end milling cutter with the spiral edge is the most common.

The helix angle is generally 30 ° and 45 °. For some workpieces with low processing requirements, generally use a 30 ° helix angle, large feed rate, and small rotation speed. If the quality of the parts is required to be high, the 45 ° helix angle should be selected, and the surface quality of the parts should be improved with a small feed rate and large rotating speed.

- tooth number selection of end milling cutter

The chip holding groove of the end milling cutter decreases with the increase of the number of edges, while the rigidity is on the contrary. The end milling cutter with more edges has better rigidity, and the rigidity affects the stability of the cutter during milling. Therefore, end mills with 3-6 cutter teeth are generally used for rough machining, while end mills with 5-10 cutter teeth are used for finish machining.

- feed of end mill

There is a taboo in the application of an end milling cutter, that is, it is generally not allowed to do the feed movement along the axial direction of the milling cutter, but it is recommended to do the feed movement along the radial direction of the milling cutter. However, if you change the processing method, you can also cut deep and feed along the Z direction. Common feeding methods are as follows.

- Use drill bit and process hole to feed. First, select the drill with a smaller diameter to process the process hole, and then use the end milling cutter to feed the vertical cutting depth in the Z direction.

- Use the screw feed method. CNC milling machine can realize three-axis linkage helix feed, which makes the natural and smooth transition between Z-direction feed and inner contour machining, and generally does not produce machining tool marks. Therefore, this method has been widely used.

- Slash feed method. The three-axis linkage oblique line feed mode is adopted, and the end edge of the end mill is used for cutting, to avoid the central part of the cutter participating in cutting. However, the disadvantage is that this feeding method can not realize the smooth transition between Z-direction feeding and inner contour machining, and it is easy to produce machining traces.

- new member of end milling cutter - carbide spiral tooth milling cutter

The diameter of the carbide spiral tooth milling cutter is larger than that of the ordinary end milling cutter. Spiral grooves are opened on the circumference of the milling cutter. Two or more carbide blades are installed in one groove, and the joints between adjacent cutter teeth are staggered. The joints between the blades of the same groove are used as the chip separation grooves. This kind of milling cutter has many blades, which are staggered with each other. It is like mature corn, commonly known as a "corn milling cutter". Because it is a spiral edge composed of multiple cemented carbide blades, the "corn milling cutter" has high strength and a large cutting force. It is mostly used for rough machining. It can have a large back feed and a large feed. The milling efficiency is very high.

- new member of end milling cutter - wave edge milling cutter

The wave edge milling cutter has a wave edge, which can effectively reduce the cutting resistance, with small vibration and high milling efficiency. The wave edge milling cutter divides the long and narrow chips into thick and short chips through the wave edge, and the chip removal is smooth; The wave edge can increase the length of the cutting edge, which is not only conducive to heat dissipation, but also convenient for the cutting fluid to penetrate the cutting area, with good cooling effect, and can be used for finishing machining.

Vertical CNC milling machine slot type commonly used tools -- keyway milling cutter

The shape of the keyway milling cutter is very similar to that of the end milling cutter, except that the keyway milling cutter is a two-edge cutter. There is no central hole on the end face. The cutter teeth on the end face are opened from the outer circle to the axis, and the helix angle is generally 30 °. The strength of the end face cutter teeth is high, so the cutting edge on the end face cutter teeth is the main cutting edge, and the cutting edge on the cylindrical surface is the auxiliary cutting edge. Unlike end mills, keyway cutters can feed either axially or radially. The slot milling cutter has only two edges, so its rigidity is not as big as that of the end milling cutter.

However, the accuracy and tolerance of the cylinder diameter are very strict, and the overall accuracy of the milling cutter is high, which also makes it necessary to select the milling cutter with the same diameter as the keyway when milling the closed round head keyway with the keyway milling cutter, and use the diameter accuracy of the milling cutter to ensure the accuracy of the keyway. When the vertical milling machine tool is not complete, we can use the keyway milling cutter to process multiple contents, such as plane, groove, contour, etc. This method is often used when students are beginning to learn that milling machines do not require high machining accuracy.

Searching for a budget cnc milling machine, dental cnc milling machine, table cnc milling machine manufacturer from China, you can get high-quality products at a nice price.