Iphutha lefomethi ye-imeyili

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Izindaba

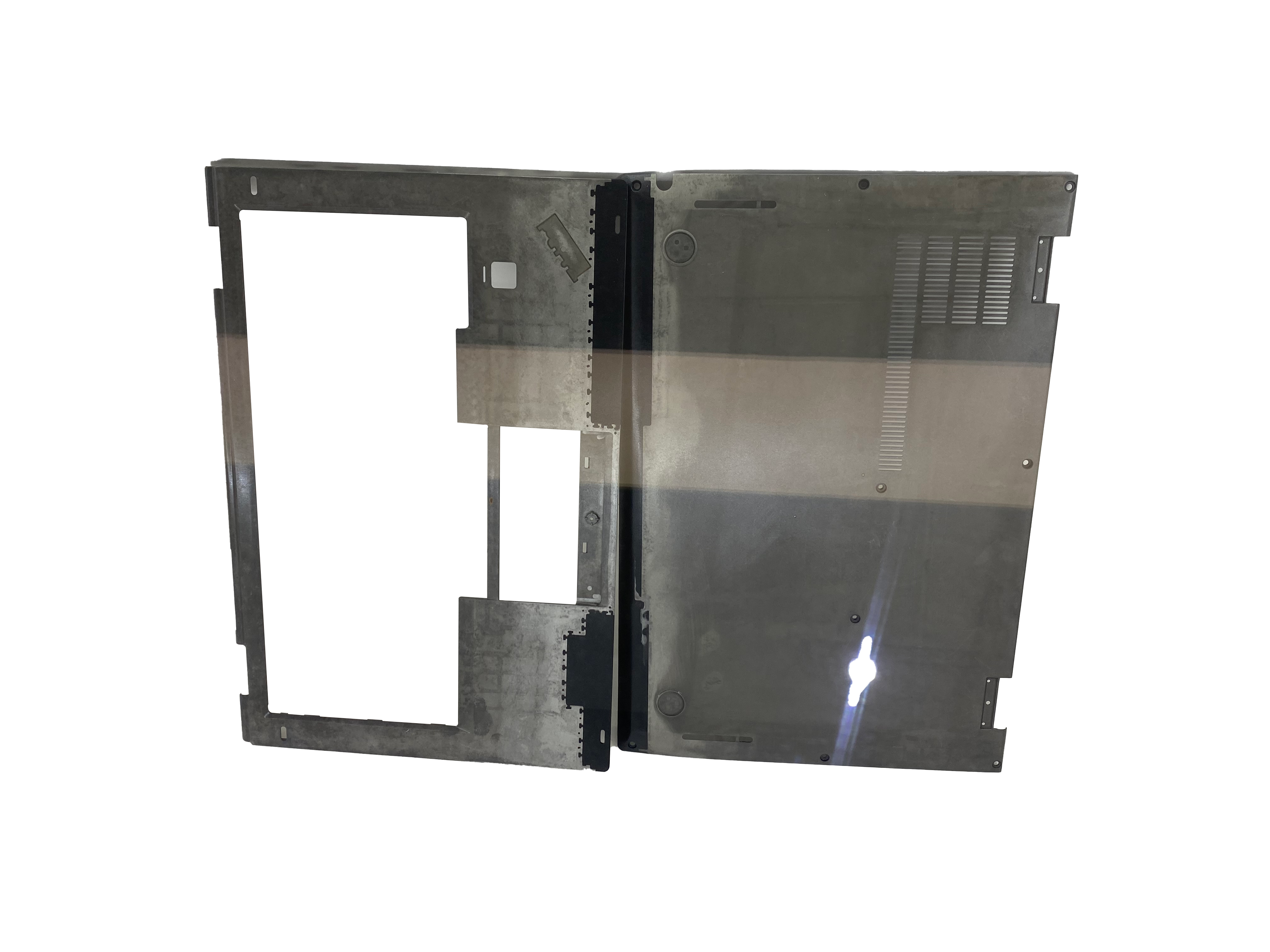

The Quality of Die Castings Is Directly Related to Die Casting Molds

Controlling the surface temperature of die-casting molds is of great significance to the production of high-quality die-casting parts. Uneven or inappropriate die casting mold temperatures can also cause dimensional instability in castings. During the production process, the casting will be ejected and deformed, causing defects such as hot pressing, sticky molds, surface depressions, shrinkage holes, hot bubbles, etc. When the mold temperature difference is large, the variables such as filling time, cooling time and spraying time in the production cycle will be affected to different degrees.

Cold bar:

Reason: The temperature in the front of the melted soup is too low, and there are traces when overlapping.

Ways to improve:

- Check if the wall thickness is too thin (design or manufacture), the diluent area should be filled directly.

- Check that the shape is not easy to fill; if the distance is too far, closed areas (such as fins, bumps), blocked areas, and corners are too small, it is not easy to fill. And watch for ribs or cold spots.

- Shorten filling time.

- Change the filling mode.

- Increase the mold temperature.

- Increase the temperature of the soup.

- Check alloy composition.

- Airway augmentation may be useful.

- Vacuum equipment may be useful.

Stomata:

Reason:

- Air is mixed in the soup.

- Gas source: melt, in feed tube, in mold, release agent.

Ways to improve:

- Moderately slow.

- Check that the channel rotates smoothly and that the cross-sectional area gradually decreases.

- Check that the area of the escape route is large enough, blocked, and at the last fill position.

- Check whether the release agent is sprayed too much and the mold temperature is too low.

- Use a vacuum.

Cavitation erosion:

Reason: Due to the sudden drop in pressure, the gas in the molten soup suddenly expands and hits the mold, resulting in damage to the mold.

Ways to improve:

The cross-sectional area of the runner should not change rapidly.

Shrinkage:

Reason: When a metal solidifies from a liquid to a solid, it takes up less space. If there is no metal replenishment, shrinkage will form. Usually occurs where the solidification rate is slow.

ways to improve:

- Increase the pressure.

- Change the mold temperature. Local cooling, spraying agent, lower mold temperature. Sometimes it just changes the position of the shrink hole, not the shrink hole.

Peel:

Reason:

- Poor filling method will cause the molten soup to overlap.

- The mold is deformed, causing the molten soup to overlap.

- Inclusive oxide layer.

Ways to improve:

- Switch to high speed in advance.

- Shorten filling time.

- Change the filling method, gate position and gate speed.

- Check that the die strength is sufficient.

- Check that the pin die device is in good condition.

- Check for oxides.

Flow orifice difference:

Reason: The molten soup is flowing too slowly, or too cold, or not filled in a good way, so there are holes in the solidified metal joints.

Ways to improve:

- Use the same method to improve cold pellets.

- Check that the temperature of the molten soup is stable.

- Check whether the hot filling of the mold is stable.

Conclusion

For more information about die casting components,die casting machine parts,hot chamber and cold chamber die casting process, we are glad to answer for you.