Iphutha lefomethi ye-imeyili

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Izindaba

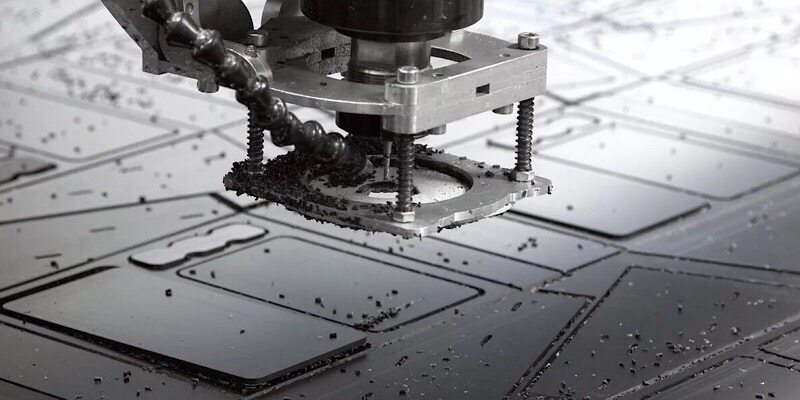

Practical CNC Plastic Processing Skills

Traditionally, NC machining has been regarded as a machining method. However, the modern industry requires the accuracy of all possible materials. This is the reason for developing CNC plastic processing technology. Now, it occupies a considerable position in high-precision, small batch production, and plastic parts manufacturing.

Why plastic parts are popular?

Why is plastic so popular? Since the invention of industrial-grade polymers, the invasion of plastics in all branches of modern industry has been unstoppable. There are many reasons for this. I will only list three main reasons. Plastic parts are cheap, light, and durable. Let's talk about the first point here. Cheap means that the cost of manufacturing them is much lower than that of metal parts.

CNC plastic processing method

There are many ways to produce high-precision plastic parts. Modern industrial-grade plastics are cast, injected, printed, or machined. The first three options are ideal for manufacturing complex geometric parts with an excellent surface finish. However, there is nothing better than machining when you need to achieve strict tolerances or produce a mirror-like surface finish on almost any type of part. About 80% of plastic parts are CNC milled. This is the most widely used method for manufacturing parts without rotating shafts. All the rest are usually opened on the lathe. To obtain an excellent surface finish, CNC machined parts are polished or chemically treated.

Plastic processing skills

Mechanical equipment

First, let's clarify. There is no plastic CNC machine. All machine tools used to cut plastics are metal processing tools. Its precise rigidity and power output enable them to easily process and even harden plastics. I want to point out that woodworking machine tools have low rigidity, so the effect is not good.

Machining tool

Choosing the best cutting tool for plastic parts is a complex task. The reason for this is that the composition of plastics and composites changes greatly. Some plastics are reinforced with hard carbide particles or have additives that can enhance flexibility, heat resistance, or other parameters. All this changes the way plastics react to machinery. Even the colorant of the material is important because, according to its type, the hue may change during processing due to a large amount of heating.

Having said that, it is obvious that the correct cutting tool geometry must be selected for the processed plastic parts. For example, milling cutters are similar to aluminum milling cutters with two grooves, but sharp edges have sharper angles. The same can be said about exercise. Their protagonist (120 degrees for metal) becomes only 60 degrees. In this way, the chips are smaller and can be removed more easily. However, you cannot use this drill on metal. It will rupture in a few minutes.

Part clamping

Please remember when clamping plastic blocks. Plastic is not metal. If the blank is clamped with too much force, it is easy to leave large marks on the surface. If you apply too much force, the part may break. If you want to avoid 100% traces, it is recommended to use special gaskets made of soft materials between the fixture and parts. Another problem is the rigidity of parts. For example, if you want to drill a fairly large part (imagine the case of a laptop). You need to pay close attention to the distance between the drilling position and the fixture. In this process, the drill will try to pull the part up along its groove. If the fixture is too far away, the drill will succeed. It will bend the parts or may tear the parts from the fixture.

Cutting parameters

Let's take a CNC milling plastic shell as an example to see the choice of the plastic cutting process. The main problem you must pay attention to is excessive friction and plastic deformation of parts, not cutting. To avoid the second problem, please always keep the knife sharp. If the material used is not strong enough, please freeze it. The plastic hardens and becomes brittle at low temperatures.

To prevent chips from melting onto CNC machined parts, you need to keep the tool moving and prevent it from staying in one position for too long and take out the chip as soon as possible. When the feed speed is large, the spindle speed must also be very fast. The approximate estimated speed is about 3 times the aluminum feed speed and has the corresponding cutting speed.

The role of plastics in the manufacture of CNC hand boards

Plastic processing services are closely related to CNC hand board manufacturing technology. Polymer materials are very suitable for hand board manufacturing and engineering verification. The reason is that plastic is easy to process. If you don't have any heating or forming equipment, making parts with CNC plastic blocks is a good way to obtain these hand boards quickly and conveniently. You can use the same widely used equipment as processing metal, so it has great flexibility. The cutting speed and feed speed will be faster, so the delivery time will be shorter, and there will be an opportunity to test your product samples faster and bring them to market earlier than your competitors.

Searching for a custom cnc plastic machining, cnc plastic machining manufacturer, plastic parts cnc machining supplier, wholesaler, manufacturer from China, you can get high-quality products at a nice price.