Iphutha lefomethi ye-imeyili

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Izindaba

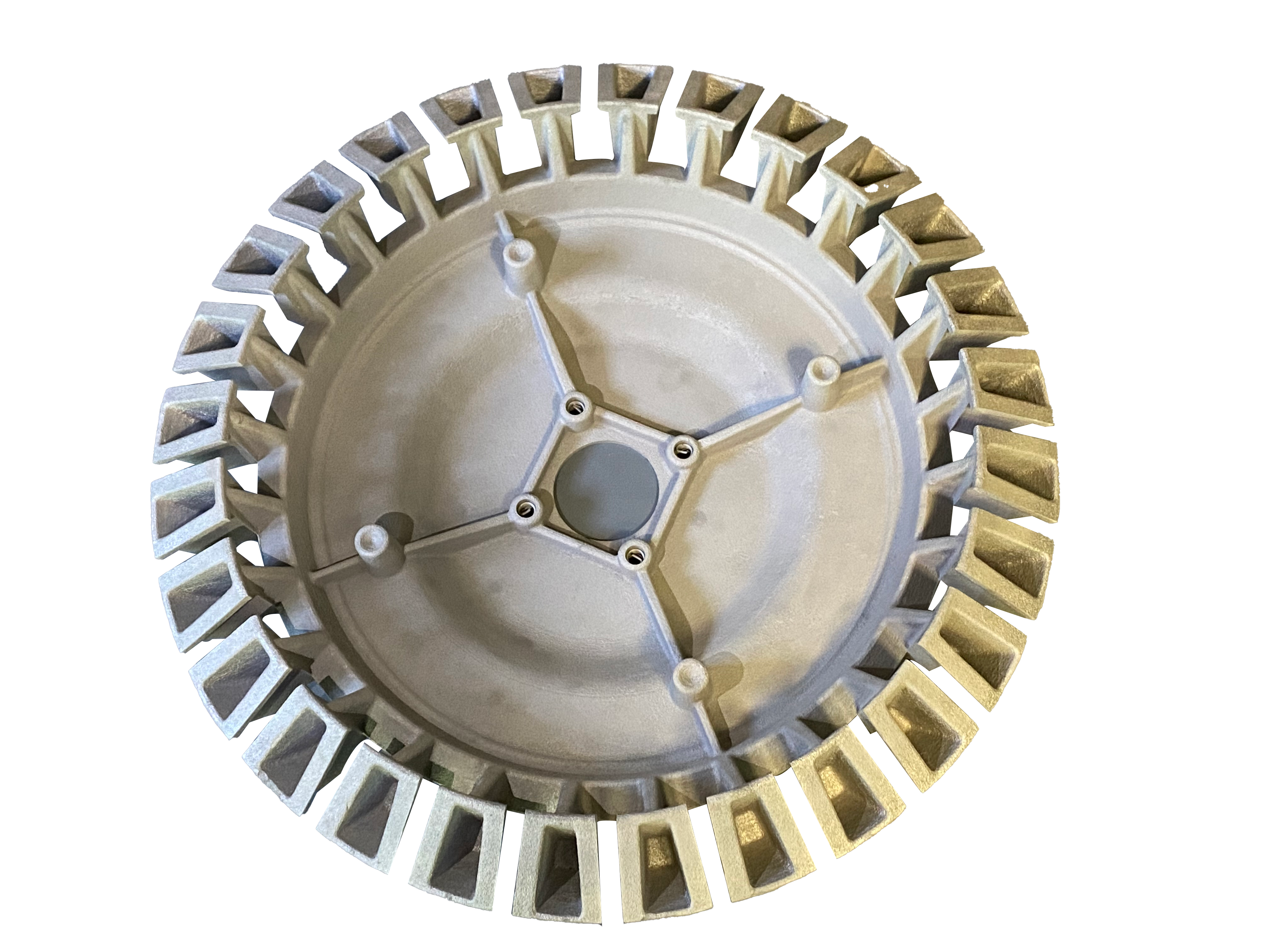

Guide for Various Surface Treatment Effects of Aluminum Alloy Precision Parts

- Sandblasting of aluminum alloy CNC machined parts:

CNC machining parts will produce knife marks in the processing process, and the pattern will be covered by sandblasting. Sand used for sandblasting is a kind of delicate glass bead. Sandblasting is generally carried out before anodizing, which can make anodized products more beautiful.

- Anodizing of aluminum alloy CNC machined parts:

Anodizing is used for aluminum alloy CNC machining parts, using ordinary anodizing and hard anodizing processes. It will make the surface of CNC parts harder, harder to wear, and more beautiful. Anodizing colors can be varied: Yellow anodizing, gold anodizing, red anodizing, green anodizing, white anodizing, pink anodizing, coffee anodizing, bronze anodizing, silver anodizing, black anodizing, and other colors. Anodizing is widely used in industrial keyboards, bicycle parts, optical lenses, motorcycle parts, automobile parts, UAVs, fishing gear, LED lights, etc.

- Electroplating of aluminum alloy CNC machined parts:

Electroplating is also the most commonly used processing technology for aluminum alloy CNC parts. Electroplating is coating the main material surface of iron or steel with zinc, chromium, gold, silver, or nickel to ensure long-term use without rusting. The main products of electroplating processing include bicycle parts, auto parts, mechanical equipment, new energy equipment parts, and instrument parts.

- Polishing of aluminum alloy CNC machined parts:

Polishing refers to a processing method that uses mechanical, chemical, or electrochemical effects to reduce the surface roughness of aluminum alloy CNC machined parts to obtain a bright and flat surface. The main materials are aluminum, steel, and titanium alloy.

- Wire drawing of aluminum alloy CNC machined parts:

Wire drawing is to draw lines on the surface of CNC machined parts through grinding equipment, which has a decorative effect. The materials used for wire drawing are usually steel and aluminum products.

- Oiling:

Oil spray is a coating method that sprays atomized paint on the surface of CNC metal parts or CNC plastic products with spray guns and other spraying tools. Fuel injection products are used in consumer electronics, beauty instruments, laser equipment, and handheld measuring instruments.

- Painting:

Spray paint is used for large CNC precision parts and sheet metal parts. Painting treatment can prevent chassis, auto parts, automation equipment parts, forklift products, and other parts from rusting.

- Quenching:

Polishing and quenching (QPQ): QPQ refers to putting CNC metal parts into two salt baths with different properties, and penetrating various elements into the metal surface to form a composite wetting layer, to achieve the purpose of modifying the surface of CNC parts.

The customized surface of sheet metal without quenching treatment will achieve the effect of surface quenching. It is a new metallurgical method with good wear resistance, corrosion resistance, fatigue resistance, and environmental protection. QPQ technology is widely used in engine valves, crankshafts, cylinder liners, gears, cams, bearings, spindles, slides, steering arms, car wiper ball joints, guide rails, hydraulic cylinders, universal joints, connecting pins, molds, pistons, threaded screws, bolts and nuts, pump bodies, high-speed steel drill bits, gun barrels, tools, flanges, keys, washers, housings.

- Physical vapor deposition (PVD):

The PVD coating technology has high hardness and wear resistance, and can still maintain a good appearance in direct sunlight. PVD can be made in a variety of colors, including yellow, gold, red, green, white, pink, coffee, bronze, gray, black, and other colors. PVD is widely used in locks, smoking sets, hand decorations, automobile decorations, handicrafts, etc.

- Electrophoresis:

The electrophoretic film has the advantages of full, uniform, flat, and flat coating. The surface of CNC machine parts can be electrophoretically coated with various colors. A variety of materials can be electrophoretic, including copper, aluminum, iron, stainless steel, aluminum alloy, zinc alloy, etc. Electrophoresis is widely used in stainless steel shell, optical accessories, ski shoe accessories, radiator, cosmetic mirror box, zipper handle, hot water bottle shell, auto parts, knives, and slides. Electroless nickel plating of CNC machining parts: electroless nickel plating involves immersing CNC parts in a chemical solution to form a chemical film on their surface. It can prevent corrosion and increase the service life of parts. This technology is widely used in automation design, machine parts, and equipment, packaging machine equipment parts, and school teaching equipment parts.

Searching for a mk precision casting, custom precision machining, precision prototyping machining supplier, wholesaler, manufacturer from China, you can get high-quality products at a nice price.